Researcher : Supan Yodyingyong

Institute for Innovative Learning, Mahidol University

High Volume – Sensitive qPCR (Ultra – Sensitive qPCR, Molecular Techniques for the Detection of Low – Density Malaria Parasitemias)

April 17, 2018

Vegan Media Formula for Cordyceps militaris Cultivation and Medicinal Cordyceps Teas

April 17, 2018A Cost – Effective Synthesis of Silica Aerogel by Ambient Pressure Drying Route

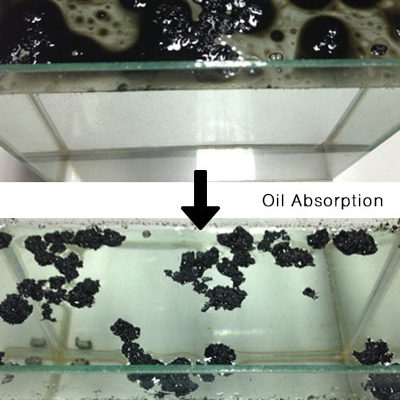

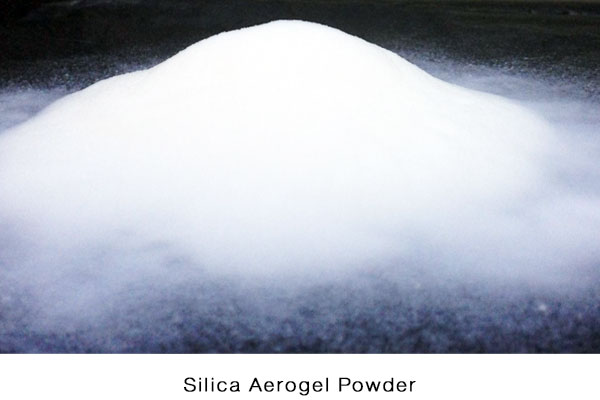

Silica aerogel is the world’s best insulating solid material. It is a nanoporous silica with an average pore size less than 100 nanometers. With the porous, sponge-like structure consisting of more than 95% of air by volume, the silica aerogel has extraordinary properties including very good thermal and acoustic insulation, high surface area, low density, and absorption of organic compounds, putting it in high demand for a wide range of industrial applications. Although its widespread uses have been restricted so far because the processes to synthesize it are complex and costly.

A spherical silica aerogel is superior to powdery and granulate silica aerogel in respect of uniformity, size control, handling, and purity. However, the existing production of high-quality of the controllable spherical silica aerogel is demanding and not sufficiently cost effective, so they have yet to be widely implemented in the industry.

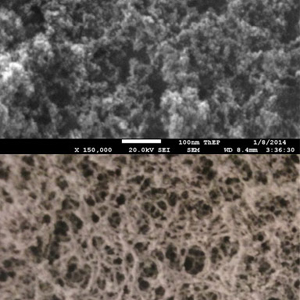

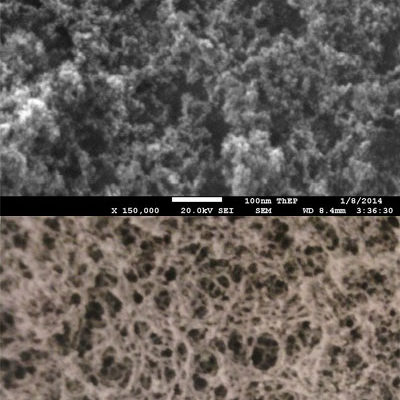

The present invention relates to a method of preparing the controllable micron-sized spherical silica aerogel using a low-cost water glass solution as the precursor at ambient conditions. The total processing time for preparation of the spherical silica aerogel is less than 5 hours. The textural properties, microstructures and chemical composition of the silica aerogel were characterized using the Brunauer-Emmett-Teller (BET) method, Field Emission Scanning Electron Microscopy (FESEM), and Energy Dispersive X-Ray Spectroscopy (EDS). The silica aerogel has bulk density of about 0.09 g/cm3, the specific surface area of 750 m2/g, and thermal conductivity of 0.020 W/m•K.

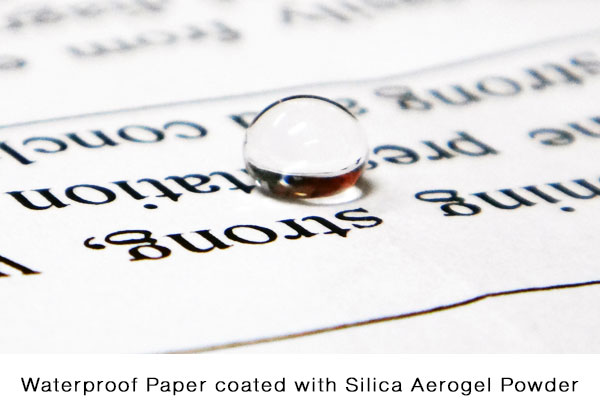

The silica aerogel can be used as an additive for the existing building, industrial, and coating products. Performance benefits include: improved thermal insulation and acoustic insulation, moisture and corrosion resistance, and weight reduction.

Utilization : Insulation Paints / Coatings, Insulation Blankets, Insulation Filler, Cement; Perlite Composites, Gypsum Boards, Plastic Composites, Absorbant

Awards :

- Outstanding Innovation Award 2015 (Chemistry and Pharmaceutical) by National Research Council of Thailand (NRCT), “Silica Aerogel – the Material for the Future”

- Mahidol University Reward 2016, Invention and Innovation Branch, “A cost-Effect Synthesis of Silica Aerogel by Ambient Pressure Drying Route”

Intellectual Property :

- USA Patent Pending, (2016) “Method of Preparing a Controllable Micron-Size Spherical Silica Aerogel”; US Provisional Patent Application: 62441218 (December 2016)

- Thai Patent Pending, (2013) “A cost-Effective Synthesis of Silica Aerogel by Ambient Pressure Drying Route; Application Number: 1301006263

Contact Person :

Dr. Supan Yodyingyong

Institute for Innovative Learning, Mahidol University

+66 2 441 9729 , +668 7219 7280

supan.yod@mahidol.edu